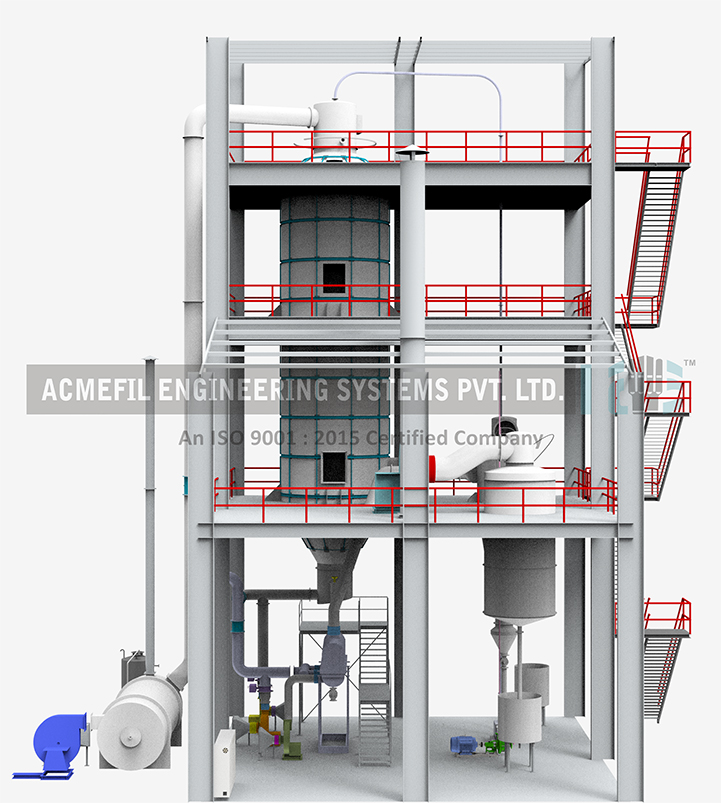

Leading Spray Dryer Manufacturer

Welcome to Acmefil Engineering Systems Pvt Ltd, your premier destination for high-quality spray drying solutions. As a renowned spray dryer manufacturer, we specialize in designing and manufacturing advanced spray dryers for diverse industries worldwide. Our commitment to innovation and excellence sets us apart in the spray drying industry.

Tailored Solutions

Custom designs and turnkey plant solutions for your needs.

Proven Expertise

Over 800 successful installations across industries.

Certified Quality

ISO 9001:2015 certified for highest industry standards.

Who we are?

Acmefil Engineering Systems Pvt Ltd

We, at Acmefil Engineering Systems Pvt Ltd, have established ourselves as a leading spray dryer manufacturer with decades of experience. Our team of experts designs and manufactures custom spray drying equipment tailored to your specific needs.

Our Mission

We aim to provide innovative and efficient spray drying solutions that enhance your productivity and profitability.

Our Vision

We strive to be the global leader in spray drying technology, recognized for our commitment to quality, innovation, and customer satisfaction.

Acmefil Engineering Systems Pvt Ltd – Leading Spray Dryer Manufacturer

Welcome to Acmefil Engineering Systems Pvt Ltd, your premier destination for advanced spray drying solutions. As a renowned spray dryer manufacturer, we specialize in designing and manufacturing high-quality spray dryers tailored to meet the unique needs of various industries. Our commitment to innovation and excellence has established us as a trusted partner for businesses worldwide.

Innovative Spray Drying Technology

We deliver cutting-edge spray drying equipment that optimizes your production processes. Our spray dryers are engineered for efficiency, reliability, and superior product quality, ensuring you stay ahead in a competitive market.

Why Choose Acmefil as Your Spray Dryer Manufacturer?

- Expertise and Experience: With decades of industry experience, we bring unparalleled expertise to every project.

- Customized Solutions: We design and manufacture spray dryers that align with your specific requirements.

- Quality Assurance: Our strict quality control ensures that every piece of equipment meets international standards.

- Comprehensive Support: From consultation to after-sales service, we provide full support to our clients.

Applications of Our Spray Dryers

As a leading spray dryer manufacturer, our equipment is utilized across a diverse range of industries and applications:

Food and Beverage Industry

Our spray dryers are essential in producing powdered forms of various food and beverage products, such as:

- Dairy Products: Milk powders, whey proteins, and caseinates.

- Beverages: Instant coffee, tea extracts, and powdered drinks.

- Flavors and Additives: Flavorings, colorants, and nutritional supplements.

We design our equipment to preserve the nutritional value and flavor integrity of food products, ensuring high-quality end products.

Pharmaceutical Industry

In the pharmaceutical sector, our spray dryers are used for:

- Active Pharmaceutical Ingredients (APIs): Drying heat-sensitive APIs while maintaining their efficacy.

- Excipients: Producing consistent and uniform excipient powders.

- Vaccines and Biologics: Drying biological products with precision to preserve their activity.

Our spray dryers meet the stringent regulatory requirements of the pharmaceutical industry, ensuring product safety and compliance.

Chemical and Material Processing

Our equipment caters to the chemical industry for applications such as:

- Catalysts and Enzymes: Producing fine powders with specific particle sizes.

- Pigments and Dyes: Drying colorants for textiles, plastics, and paints.

- Ceramics and Advanced Materials: Processing materials for electronics, aerospace, and other high-tech applications.

We engineer our spray dryers to handle corrosive and abrasive materials, ensuring durability and longevity.

Environmental Applications

Our spray drying technology contributes to environmental sustainability through:

- Waste Treatment: Converting liquid waste into manageable powder form.

- Flue Gas Desulfurization: Removing pollutants from industrial emissions.

- Recycling Processes: Recovering valuable materials from waste streams.

We provide solutions that help industries reduce their environmental footprint.

Our Spray Dryer Features

As a top spray dryer manufacturer, our equipment offers:

- Energy Efficiency: Optimized designs that reduce energy consumption.

- Advanced Control Systems: Precise control over temperature, airflow, and feed rates.

- Scalability: Equipment suitable for small-scale to large-scale production.

- Safety Measures: Built-in safety features to protect operators and equipment.

Customized Solutions for Your Needs

We understand that each client has unique requirements. Our team works closely with you to design and manufacture spray dryers that align with your specific processes and goals.

- Process Evaluation: We assess your production needs to recommend the best solutions.

- Design and Engineering: We create detailed designs using the latest technologies.

- Installation and Commissioning: Our experts ensure seamless setup and operation.

- Training and Support: We provide comprehensive training and ongoing support.

Quality Assurance

We are committed to delivering equipment of the highest quality. Our manufacturing processes adhere to international standards, and we conduct rigorous testing to ensure reliability and performance.

- ISO Certification: We maintain ISO-certified quality management systems.

- Material Selection: We use high-grade materials suitable for your application.

- Testing Procedures: We perform thorough inspections and performance tests.

Innovation and Research

We invest in continuous research and development to stay at the forefront of spray drying technology.

- Latest Technologies: We incorporate cutting-edge advancements such as automation and data analytics.

- Process Optimization: We focus on improving drying processes to enhance efficiency and reduce costs.

- Sustainability Initiatives: We develop environmentally friendly solutions to promote sustainable practices.

Customer Success Stories

We have partnered with numerous clients across various industries to provide customized spray drying solutions.

- Food Manufacturer: Increased production efficiency by 30% using our energy-efficient spray dryers.

- Pharmaceutical Company: Achieved consistent product quality and compliance with regulatory standards.

- Chemical Producer: Reduced waste and improved product uniformity with our advanced drying technology.

Global Reach

As a leading spray dryer manufacturer, we serve clients worldwide, offering:

- International Standards Compliance: Our equipment meets global industry standards.

- Export Services: We handle logistics to deliver equipment globally.

- Local Support: We provide support services to clients across different regions.

Partner with Acmefil Engineering Systems Pvt Ltd

By choosing Acmefil as your spray dryer manufacturer, you gain a partner dedicated to your success. We strive to enhance your production capabilities and deliver value through our innovative solutions.

Get Started with Acmefil

Take the first step toward optimizing your production with our advanced spray drying solutions.

- Request a Quote: Contact us to receive a customized quote based on your needs.

- Consultation: Schedule a consultation with our experts to discuss your project.

- Visit Our Facility: We welcome you to visit our manufacturing facility to see our capabilities firsthand.

Our Clients

Why Choose Us ?

ACME – as the meaning is – ‘THE HIGHEST POINT OF PERFECTION’ and Acmefil today strives to fill in the gap between the PRESENT & ACME.

- 24+ years of industrial experience

- ISO 9001:2015 Certified Company

- Latest and Most Advanced Manufacturing Technology

- 20 + Engineers After Sales Services, Installations, and Commissioning Team

- OEM Spare Parts and Maintenance Contract